BOSTON… Emerson Bearing Boston, a bearing company catering to OEM (Original Equipment Manufacturers) and MRO (Maintenance, Repair and Operations) markets, has recently launched a Golf division to specifically cater to the bearing needs of golf courses and facilities utilizing golf carts throughout the U.S.

Emerson Bearing Boston’s Golf division was created to meet increased demand and significant growth in this particular market over the past two years.

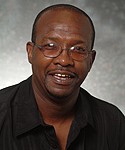

Emerson Bearing Boston has appointed Richard Furtado to lead the Golf division. A resident of Boston and Emerson Bearing’s Senior Sales Expert, Furtado has been with the company for more than three decades. He graduated from Clark Atlanta University in Atlanta, GA with a degree in Business Management and over the years has received additional training and accreditation at Emerson Bearing Boston.

Furtado will assist clients in determining which bearing technologies would be most suitable by taking into consideration the specifications, recommendations, maintenance strategies, fatigue life and wear resistance of the bearing in relation to the application.

Bearings for the golf cart market must be able to withstand outdoor environments and for this, Emerson Bearing Boston provides mounted units with triple lip seals and ball bearings with full contact sealing. They also provide spherical bushings, spherical roller bearings, tapered roller bearings, adhesives and sealants, rod ends, oil seals and mounted units. Emerson Bearing Boston carries a full range of brands for this market including SKF, FAG and KVC, as quite often, customers choose a brand based on price point.

To reach Richard Furtado in the Golf division, contact 866-995-8761 or email rfurtado@Emersonbearing.com.

Bearing Failure Analysis

As part of their customer care, Emerson Bearing Boston provides clients with the unique service of “Bearing Failure Analysis” which helps them determine the cause of bearing failure so that they may prevent future failure and predict reliability. This unique program may be accessed within the Technical Toolbox on the Emerson Bearing website.

The Emerson Bearing Difference

In a proud tradition, the same families that started the company in 1957 keep Emerson Bearing Boston rolling by specializing in bearings for OEM and MRO markets throughout the world. Emerson Bearing’s highly knowledgeable staff, operating from their 23,000 square foot facility, provides bearings ranging in size from 3mm to tunnel-boring 15-foot-diameter giants.

Emerson Bearing Boston provides solutions to a variety of industries including: aggregate, concrete, mining, machine tools, electric motor repair, marine, material handling, metal processing, packaging, food processing, paper converting, printing, wind/power generation, recreation, heavy construction, robotics, automation, transportation, wood products, wastewater treatment, pump, compressor and oil field.

Emerson Bearing Boston offers customers a one-stop shopping experience with an online product catalog with over 3 million bearings; a vast inventory of bearings; worldwide sourcing; a fixed price program; a knowledgeable staff dedicated to delivering; same day shipping and 24/7 service. They are the sister company of Action Bearing and maintain headquarters at 201 Brighton Ave. Boston, MA. For more information, contact 617-782-1400 or toll free, 800-225-4587, email info@emersonbearing.com or visit http://www.emersonbearing.com.

Golf Cart Market is Tap In for Emerson Bearing BostonRead More

Follow Us!